These properties make brass rivets ideal for applications in the oil and gas industry. Brass : Brass is an alloy of zinc and copper that has exceptional corrosion resistance and strength, and cannot spark.Low-carbon steel is preferred as it is more ductile than rigid, high-carbon steel. Steel : Carbon steel rivets are usually solid or hollow shank and must be installed using pneumatic or hydraulic equipment.Copper : Copper has an excellent electrical and thermal conductivity in addition to being relatively easy to form.Pneumatic rivet guns are recommended for installing blind stainless steel rivets.

#RIVET TYPES WIDENING INSTALL#

However, due to their hardness, they’re difficult to install with hand-operated rivet tools. Stainless Steel : Stainless steel rivets have excellent corrosion and weathering resistance.These rivets can be easily deformed and, as such, blind rivets made from aluminum can be installed with a hand-operated rivet tool. They’re lightweight and have good corrosion and weathering resistance. Aluminum : Aluminum rivets are the most common.Rivets are made from a range of different materials suited to specific applications. Industries that most commonly rely on the use and function of rivets include the automotive, aerospace, marine/naval, construction, aviation, and manufacturing industries. Rivets are typically made from either aluminum or steel, though other materials like copper are also used. Many different grip lengths are available for each hole size to accommodate different sheet thicknesses. When selecting rivet sizes, it’s critical to consider the grip length and the size of the hole.

#RIVET TYPES WIDENING MANUAL#

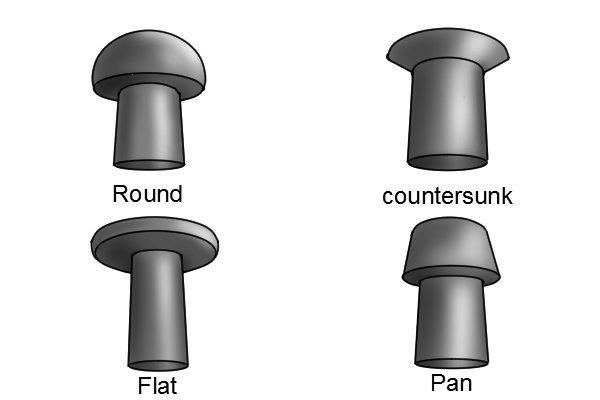

In general, rivets are installed via pneumatic or manual hammering, hydraulic pressing, and handheld rivet guns that are either manually or pneumatically operated. This permanent deformation is achieved using a range of tools that are dependent upon the type of rivet being used. To install, a rivet is inserted into a slightly oversized hole, then undergoes a process that permanently deforms it via a compressive force. Each rivet is composed of a head, a shank, and a tail. What is a Rivet and how Does it Work?Ī rivet is a permanent mechanical fastener that is designed to join two or more parts together, and there are numerous types of rivets. This article will explain how rivets are typically installed, what materials are used, and describe some commonly used rivets. Rivets are low-cost and come in a range of different materials like aluminum, stainless steel, and copper. They’re typically used to attach sheet and structural members, and in some cases only require access to one side of the joint to install.

Rivets are a versatile and low-cost method for fastening two components together.

0 kommentar(er)

0 kommentar(er)